Solutions 4.0 for the food value chain

A world of opportunities to improve the efficiency, safety, quality, traceability and sustainability of the food chain.

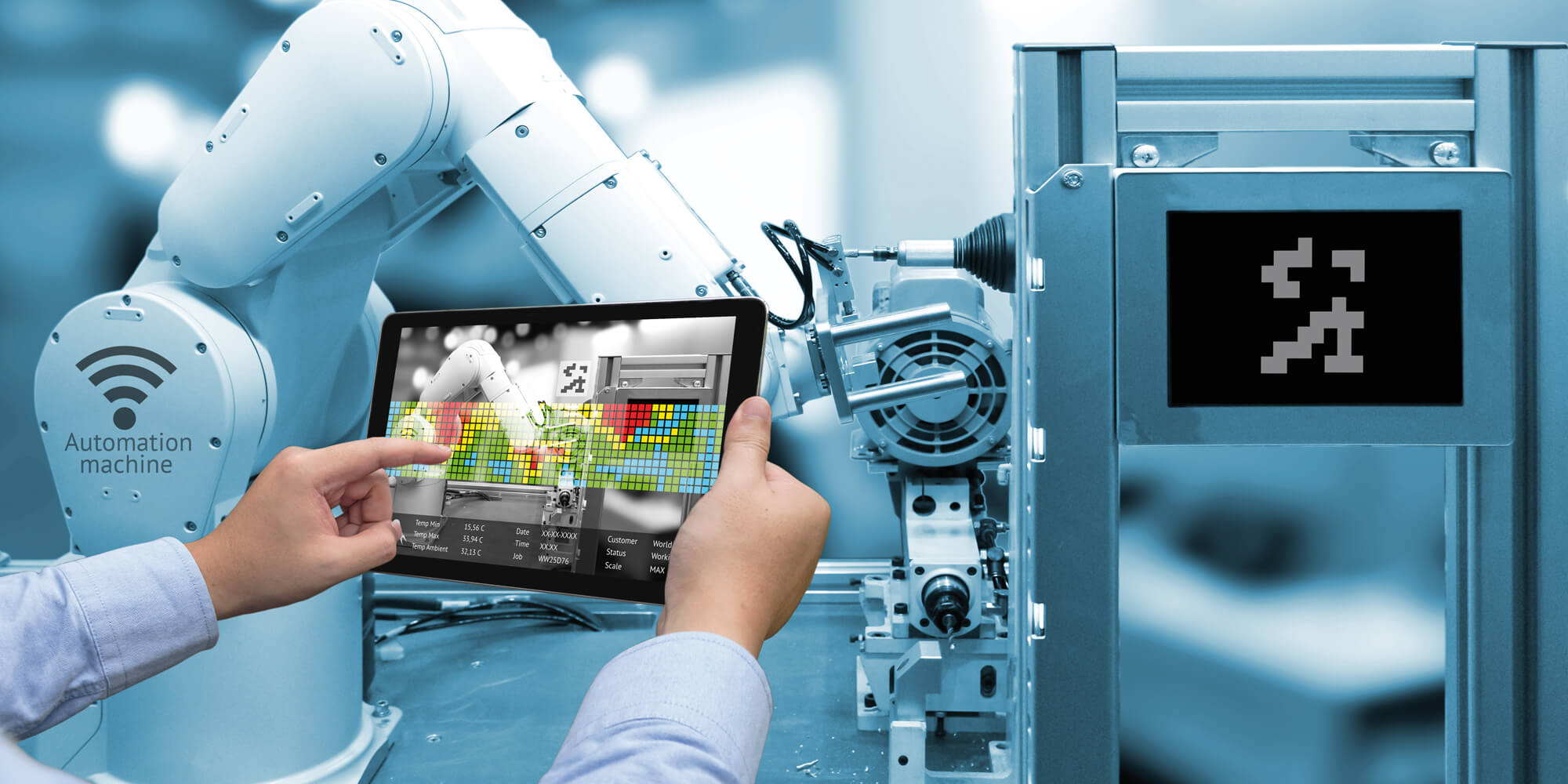

The development of new digital technologies, Internet and new connectivities open up a world of opportunities to improve the efficiency, security, quality, traceability and sustainability of the food chain.

The industry 4.0 concept is based on the automatic and intelligent capture and use of information, thanks to the new digital technologies. This transformation requires rapid information that will permit anticipating unforeseen events, and thus exponentially help to manage the business.

AZTI has been working for years to favour the gradual and full implementation of the transformation 4.0, adapted to the needs of each company and, above all, to their objectives, reality and value chain.

The main lines of expertise

- Advanced sensors: development of smart solutions to ensure food product and process quality, thus helping to increase the value chain efficiency and consumer trust. Through the identification, and fast and non-destructive measurement of critical quality and process parameters, it is possible to increase efficient and integrate differentiating elements that give value to their food products and processes.

- Benefits of advanced sensors:

- Inspect 100% of the production.

- Standardise product quality.

- Reduce product losses and waste.

- Improve traceability.

- Anticipate unexpected events.

- Ad-hoc calibrations in sensors:

development and maintenance of calibrations for sensors (UV/VIA/NIR, RF, MW,

etc.) for different food applications:

- Food transformation sector: mass quality, texture,…

- Fisheries sector: fish freshness, content, type and degree of fat oxidation, identification of fresh/defrosted product, shelf life,…

- Fruit and vegetable sector: degree of product ripeness, soluble solid content, dry matter, shelf life,…

- Meat sector: fat content, degree of oxidation,…

- Ingredients sector. moisture, presence of toxins,…

- Beverage sector: control of product/water mix, push optimisation, waste/losses management,…

- Quality predictive and prescriptive models: Development of product and process quality predictive and prescriptive models: Data Science applied to quality prediction that will permit adjusting the production in agreement with different parameters, and anticipate unexpected events.

- Personalised diagnoses 4.0: Exhaustive diagnosis of food industries based on a knowledge of their processes, in order to evaluate the degree of implementation of different technologies 4.0, as well as the needs and barriers found in this area. Preparation of roadmaps to progressively help them in their journey towards transformation 4.0, adapting to their needs, objectives and value chain.

- Economic-environmental assessment and ecodesign. Development of product and process eco-design, and economic-environmental assessment computer tools thatare specific for a sector or a company, making it possible to propose cost-saving measures, and give added value to the activity from an environmental and economic viewpoint. Web environment tools and desk linked to the ERP system.

- Example of products:

- ECO tool – Production and environmental enhancement software for the food industry: first ‘friendly’ tool for industrial use, that facilitates the identification of the main consumption points, associated economic costs, and environmental impact of food industries, as well as the simulation of new production scenarios.

- LOGISTIKA software – GIS application to optimise raw milk collection, transport and delivery circuits: this is a GIS (Geographical Information System) tool that users can personalise, thanks to intuitive and easy-to-handle interfaces.

- Traceability and quality control. Integration of traceability and quality control in advanced systems such as Blockchain technology, in order to satisfy an increasingly greater need for transparency for consumers, as well as to improve production and management between the chain operators.

- Rapid systems or detection solutions (“kits”). Development of rapid systems or detection solutions (“kits”) of quality and food security parameters adaptable/connectable to existing solutions 4.0.Development of molecule presence recognition and prediction systems for rapid control of raw material, intermediate products and finishes, labelling and compliance with set parameters,….

- Understand and interact with consumers. Solutions and services to understand and interact with consumers, through platforms, apps, gamification, sensor systems to identify emotions, development of precision nutrition solutions, data analysis and processing,…