PICKNPACK

Flexible food packaging systems

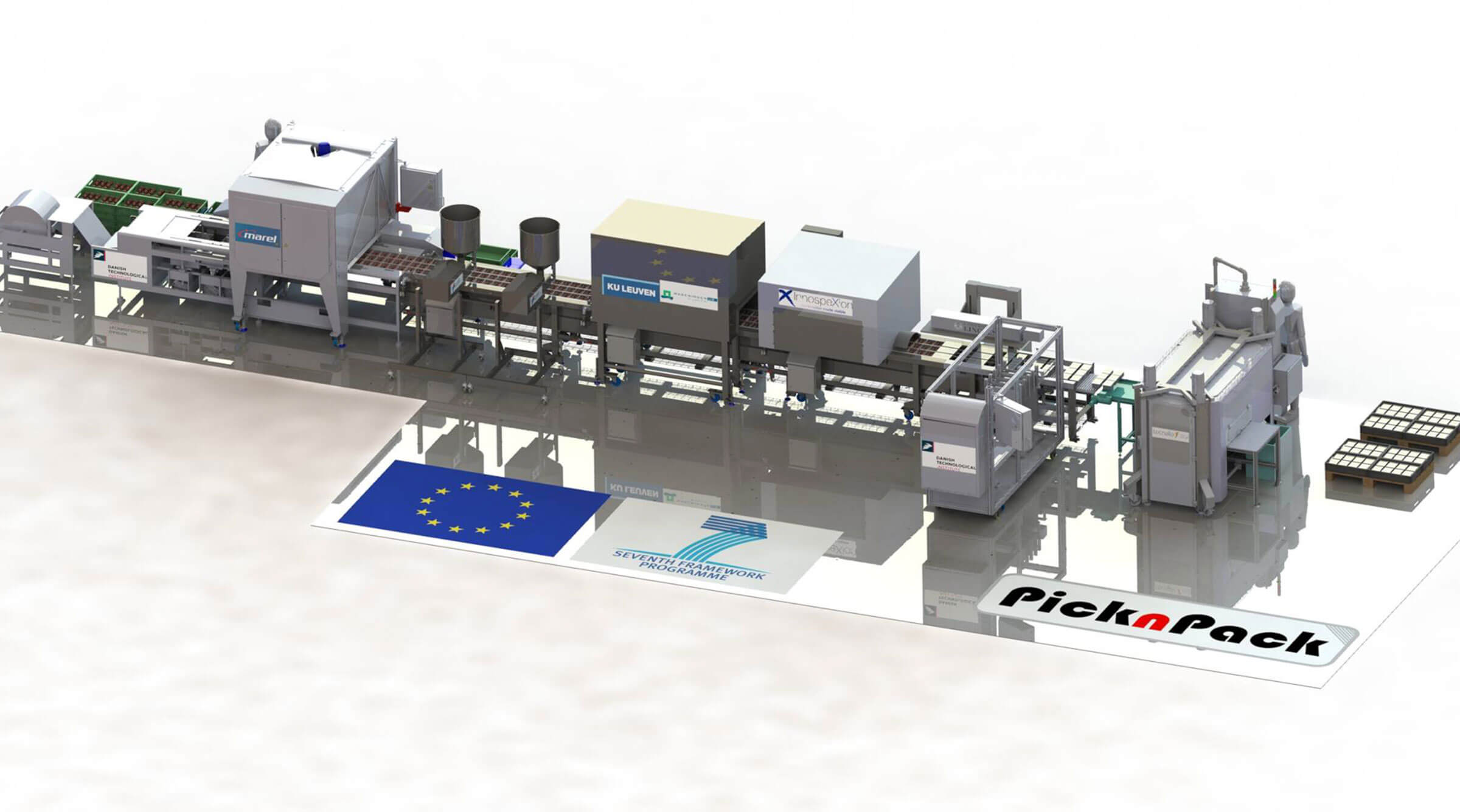

The project will develop three types of modules that can cope with the typical variability of food products and the requirements of the sector regarding hygiene, economics and adaptability, which will be working closely together:

- A sensing module that assesses quality of the individual or small batch products before or after packaging.

- A vision controlled robotic handling module that picks up and separates the product from a harvest bin or transport system and places it in the right position in a package.

- An adaptive packaging module that can accommodate various types of packaging with flexibility in terms of package shape, size, product environment, sealing and printing.

These modules connect to a multi-point framework for flexible integration into a production line that optimally makes use of the capabilities of the modules.

The communication is based on a shared, vendor-independent vocabulary. The combination of modules will be with a user-friendly interface and all modules are equipped with automated cleaning systems to ensure hygiene. All available information in the production chain and the information produced by the sensors in the system is combined, stored and made available to the different modules and both upstream and downstream in the chain. With added intelligence, this will lead to maximum performance in quality, reducing change over time, reducing time for reprogramming, adaption to operators, reducing waste of food and packaging material and stock. Human intervention will be reduced to a minimum.

Project Data

| Partners |

The PicknPack consortium has been set up in such a way that all the expertise and capabilities are available for the execution of the project and the achievement of these goals. The consortium consists of 14 participants |

| Financed by |

European Comission. DG Research |